Optimize your maintenance

Of your critical assets with predictive technology and IoT monitoring

THE FUTURE of maintenance is here: Real-time monitoring and PREDECTIVE MAINTENACE WITH AI

Reduce downtime, optimize operations, and stay ahead with

IoT-powered maintenance

Manage the entire asset maintenance lifecycle

Reduce downtime and optimize operations with real-time asset monitoring and predictive maintenance.

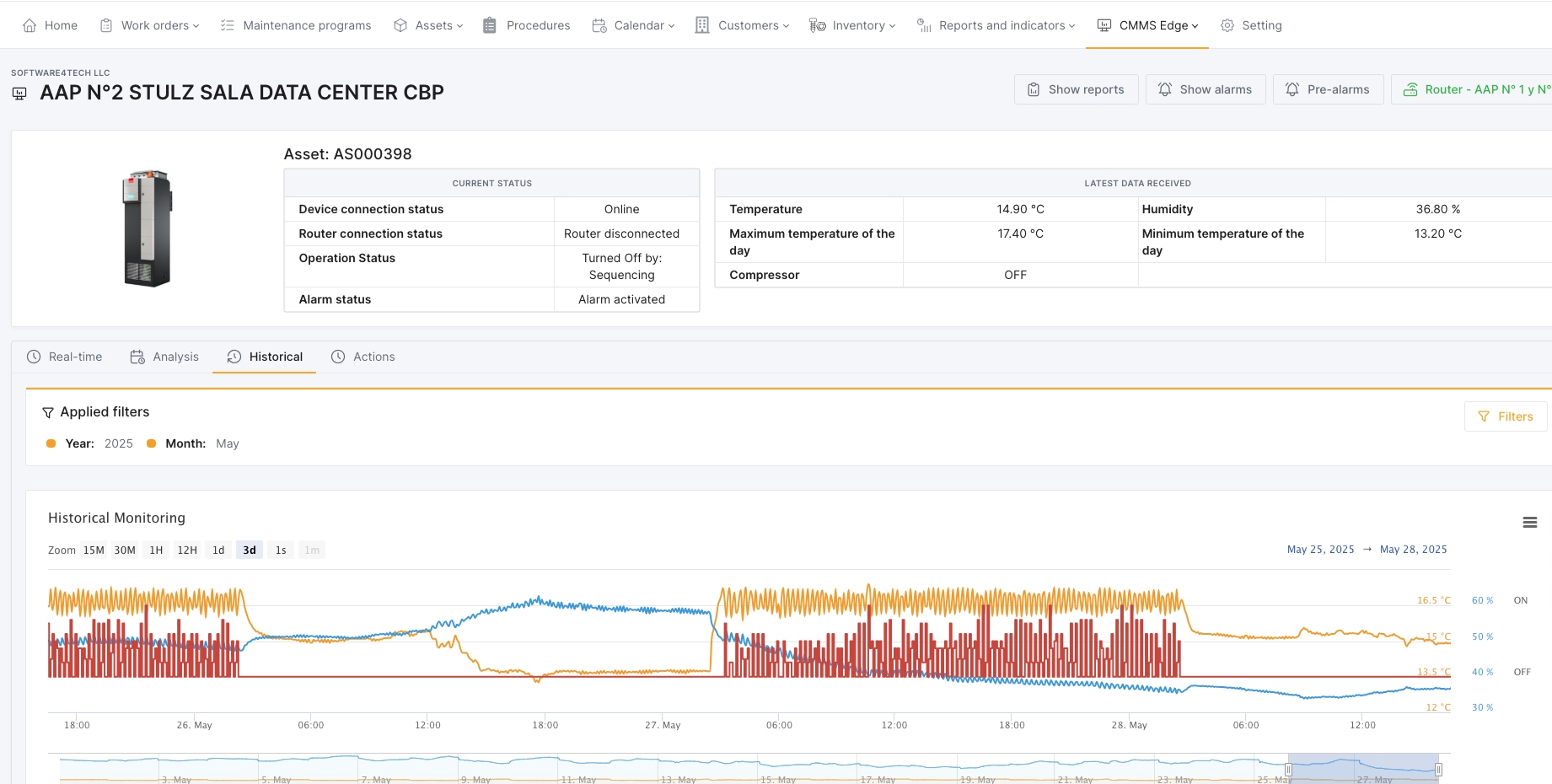

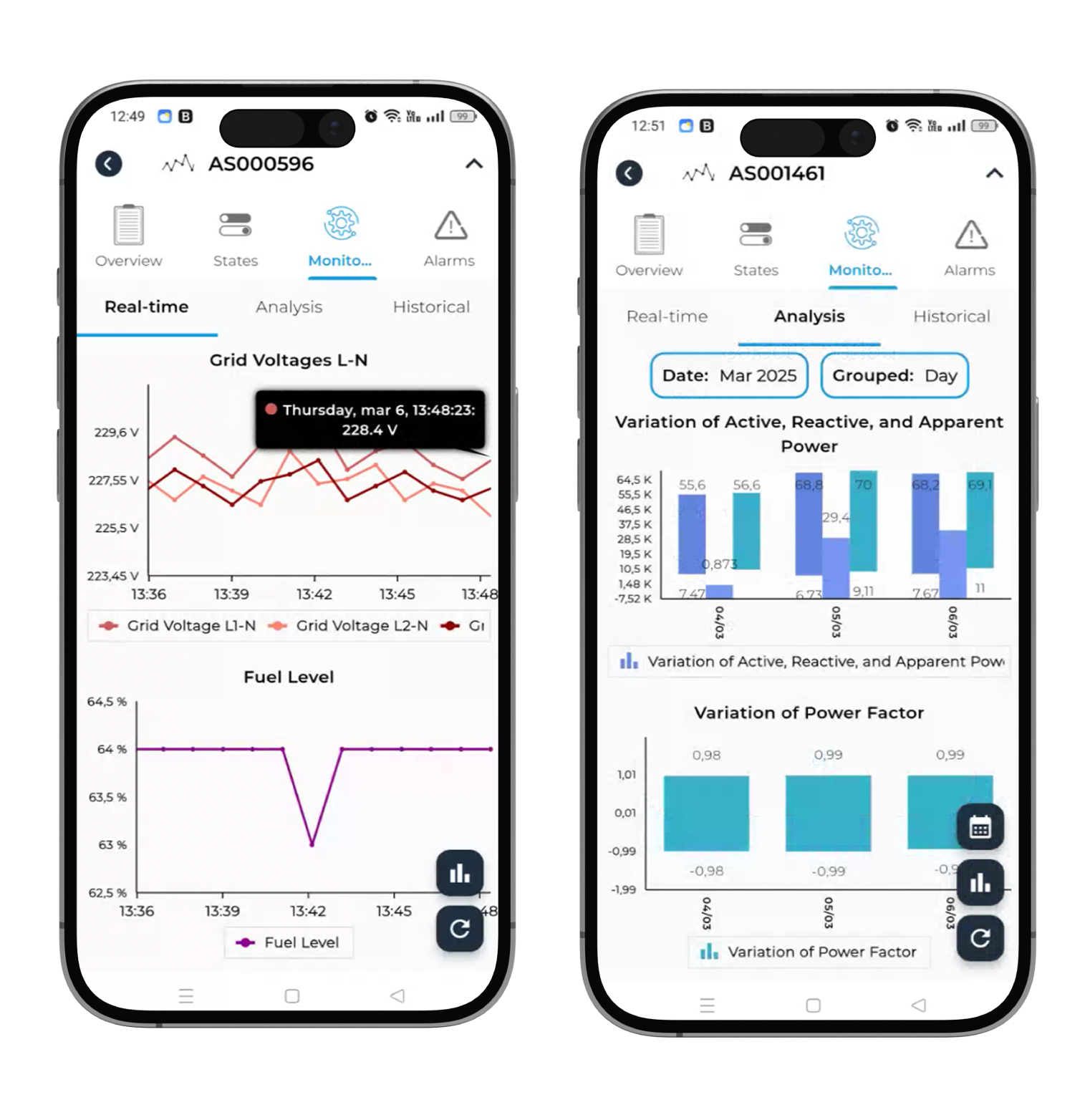

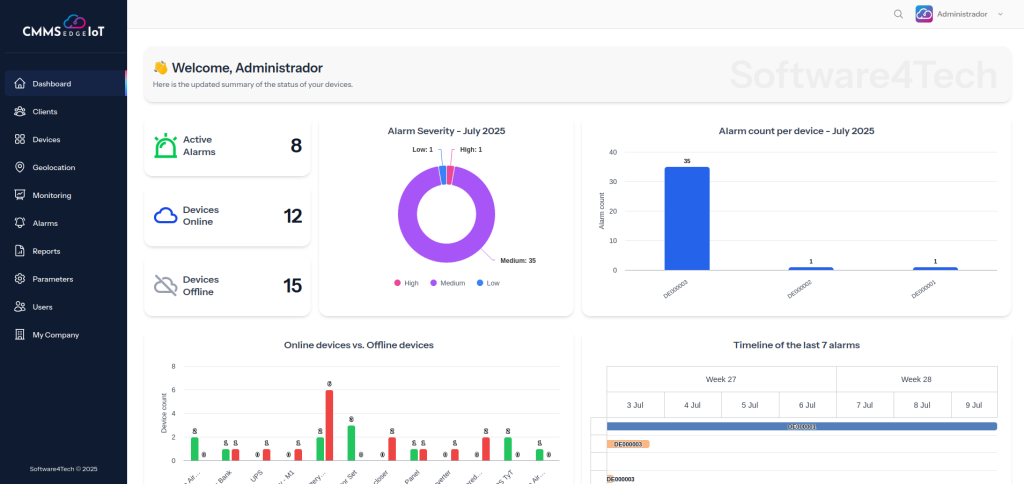

Monitor assets in real time

Manage maintenance lifecycle with AI-driven tools and dashboards.

Manage your team of technicians in real time

Real-time alerts for technical teams to act immediately.

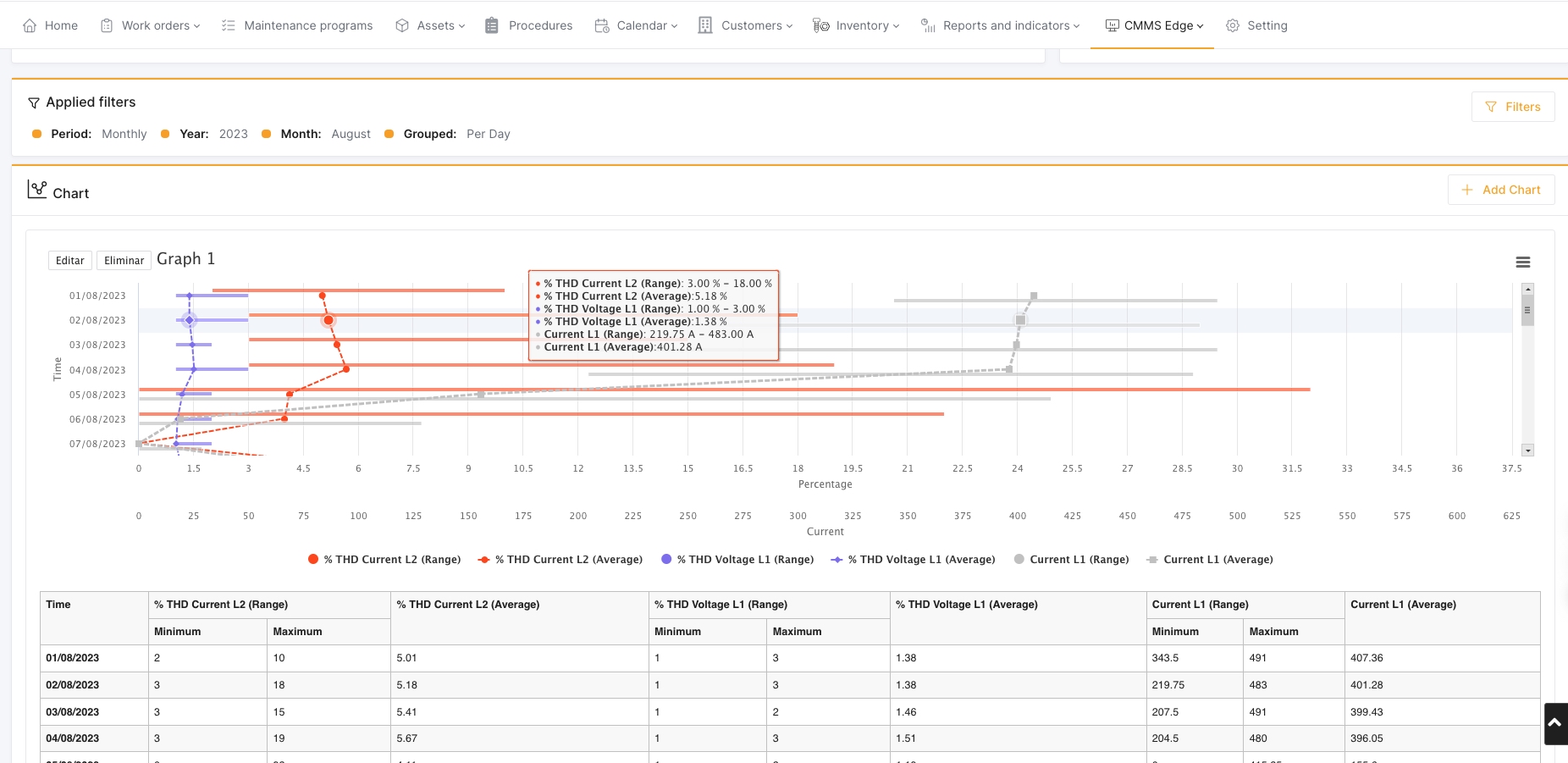

What cannot be measured cannot be managed

Visualize data trends with intuitive dashboards and predictive analytics

Your Challenges, Our Solutions

Addressing the Key Pain Points with Real-Time Monitoring and Predictive Maintenance

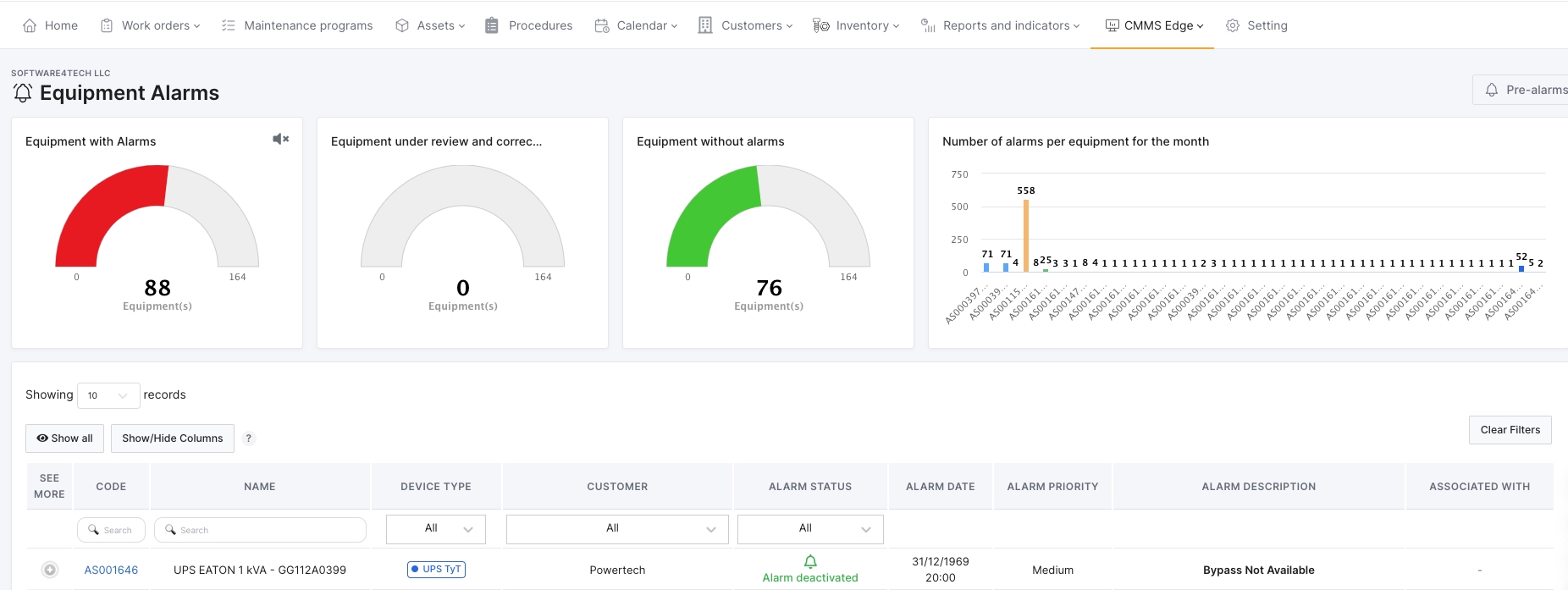

Lack of Visibility into Asset Status

Limited real-time data leads to unexpected failures and downtime. Fragmented information makes decision-making difficult. Higher costs and reduced efficiency result from poor visibility

Real-Time Monitoring and Predictive Insights

Gain full visibility into asset performance with IoT-powered monitoring. Centralize critical data in intuitive dashboards for smarter decisions. Prevent failures and reduce downtime with predictive maintenance.

Unexpected downtime

Equipment failures disrupt operations and increase costs. Reactive maintenance leads to inefficiencies and delays. Downtime impacts productivity and customer satisfaction.

AI-Powered Predictive Maintenance

Identify potential failures before they occur with advanced AI algorithms. Schedule maintenance proactively to minimize downtime and disruptions. Enhance productivity and reduce costs with data-driven insights.

Difficulty Assigning Tasks to Technical Team

Manual task assignment leads to delays and miscommunication. Lack of centralized tools complicates tracking and follow-ups. Inefficient task allocation reduces team productivity.

Efficient Work Order Management via Mobile App

Assign tasks instantly and seamlessly through the mobile app. Track progress in real-time with centralized work order updates. Improve team coordination and boost productivity with streamlined workflows.

Scattered and Hard-to-Analyze Information

Data stored in multiple systems complicates decision-making. Lack of unified insights hinders performance tracking. Time-consuming manual processes reduce efficiency.

Centralized and Intuitive Dashboards with Trend Analysis

Access all critical data in one place with centralized dashboards. Visualize trends and key metrics for faster, data-driven decisions. Save time and improve efficiency with automated analytics.

CMMSedge Applications in Industries and IoT Technologies

Manufacturing

The software addresses problems such as unexpected equipment failures and high maintenance costs. Thanks to its ability to continuously monitor critical equipment and perform predictive maintenance, CMMSedge helps reduce downtime and optimize production processes, improving operational efficiency and reducing costs.

Energy

CMMSedge provides advanced IoT monitoring for assets such as transformers and generators. This allows for greater operational visibility, improved reliability and energy efficiency, and reduced risks of failures in electrical grids, ensuring continuous and high-quality service.

Oil and Mining

CMMSedge becomes a strategic ally for the management of critical assets in demanding and high-risk environments. In the oil sector, the software allows for real-time monitoring of equipment such as pumps, valves, and drilling systems, detecting anomalies before they become major failures. This ensures safer operation, reduces the costs associated with unplanned interruptions, and optimizes the efficiency of extraction processes. On the other hand, in the mining sector, CMMSedge facilitates the predictive maintenance of heavy machinery and transportation equipment, which are fundamental for operations in underground and open-pit mines. Thanks to the integration of IoT technologies, the software ensures greater equipment availability, minimizes downtime, and improves productivity in environments where every minute counts. Additionally, its ability to generate automatic alerts contributes to preventing accidents, ensuring a safer work environment for operators.

Telecom

Failures in transmission equipment and networks generate service interruptions, affecting the customer experience and increasing operating costs. CMMSedge monitors the status of your critical equipment in real-time and uses predictive maintenance to anticipate failures before they occur. It ensures service continuity, reduces interruptions, and optimizes maintenance costs, improving the quality of operations.

Logistics

Downtime in fleets and logistics equipment generates delivery delays and increases operating costs. CMMSedge connects your logistics assets and uses IoT sensors to perform preventive and predictive maintenance, ensuring their availability. It reduces downtime, improves operational efficiency, and ensures on-time deliveries, strengthening the supply chain.

Health

The malfunction of critical medical equipment and operational support can jeopardize patient safety and affect the reputation of healthcare institutions. CMMSedge constantly monitors the status of medical assets and issues predictive alerts to prevent unexpected failures. It ensures reliable operations, extends the useful life of equipment, and improves the quality of care in hospitals and clinics.

Facility Management

The lack of proactive maintenance in buildings and spaces can result in costly failures, operational disruptions, and unsafe environments. CMMSedge integrates IoT technology to monitor your assets in real-time and plan maintenance efficiently. It optimizes facility management, reduces operating costs, and ensures a safe and functional environment for users.

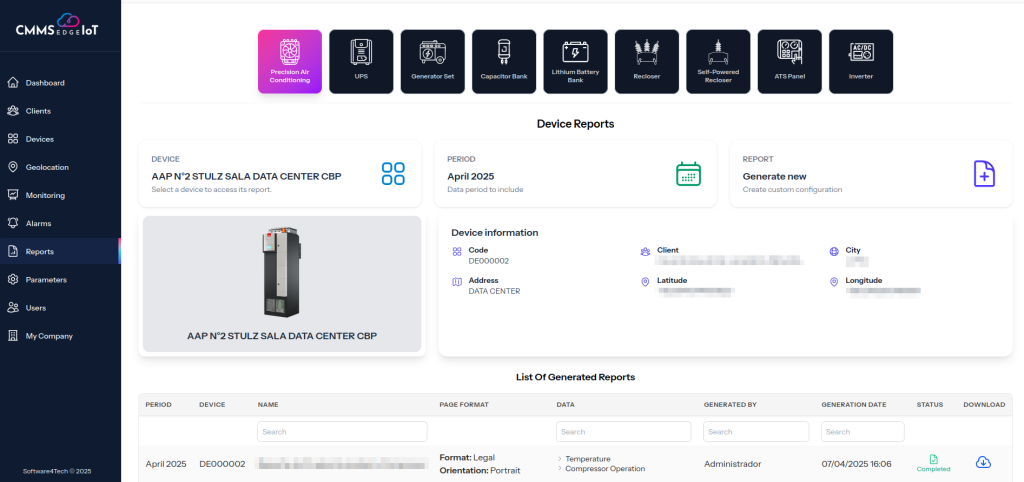

IoT Technologies Integrated in CMMSedge

Connect your assets and transform maintenance management.

CMMSedge uses advanced IoT technologies to provide a comprehensive solution that optimizes the monitoring, analysis, and maintenance of your critical assets. With these tools, you can anticipate problems, make data-driven decisions, and improve operational efficiency.

Smart Sensors

Monitor key parameters such as vibration, temperature, pressure, and humidity in real-time. These sensors detect anomalies before they become serious problems, allowing you to act proactively.

IoT Gateways

Collect data from multiple devices and send them to the CMMSedge central platform. The gateways ensure efficient and secure communication between your assets and the system.

Cloud Platform

Stores and processes large volumes of data in the cloud. CMMSedge uses advanced analytics to identify trends, predict failures, and generate detailed reports that facilitate decision-making.

Interactive Dashboards

Visualize all the information about your assets in one place. CMMSedge’s dashboards are intuitive and customizable, allowing you to monitor the status of your equipment, review key metrics, and plan maintenance strategies.

What our clients says

CMMSdge is the software that facilitates the work of asset management. The ease of use as it is an intuitive software compared to other softwares within the market. Douglas. Support Engineer.

Software4tech LLC. United States Headquarters